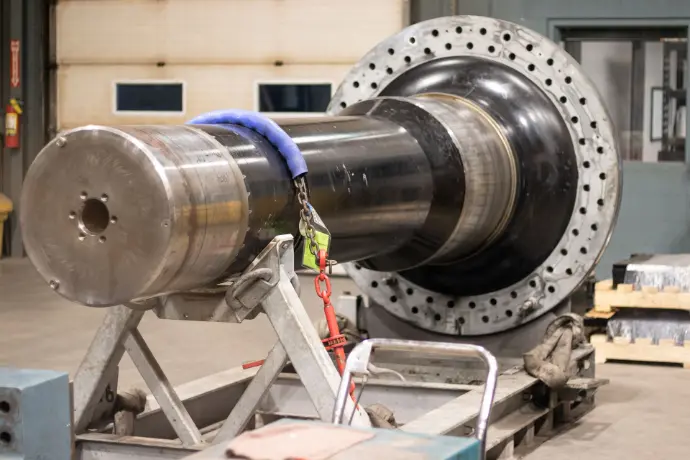

The main function of a wind turbine main shaft, like the one pictured below, is to transmit the rotational energy of the turbine blades to the gearbox - then ultimately to the generator. With modern wind turbine blades weighing upwards of 10 tons each, over time the bearing journal of the main shaft can become worn and in need of repair.

Worn turbine main shaft arrives at our facility in need of repair

Worn turbine main shaft arrives at our facility in need of repairPART AND PROCESS INFO

Component: Wind turbine main shaft

Weight: 20,000lbs (approx.)

Size: 2.3mw

Length: 148" (approx.)

Diameter: 32" (approx.)

Turnaround time: 4 days

Work Performed: Pre machining, wire laser cladding (added 0.080" of material), post machining

Tolerance: 0.002"

Material: Modified 410SS (37 HRC)

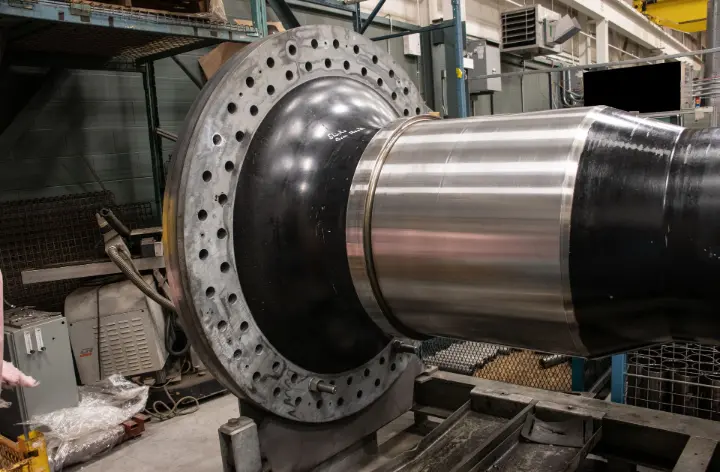

Turbine bearing journal post-cladding

Turbine bearing journal post-cladding ADVANTAGES

Better Efficiency - The use of wire laser cladding offers a 100 percent deposition efficiency, meaning there is no waste.

Metallurgical Bond- The intense, focused heat of the laser metallurgically bonds the substrate with the overlay creating a new homogeneous surface. Laser clad coatings offer minimal dilution of the base material (unlike other arc welding processes). They also offer superior adhesion compared to thermal spray coating methods such as HVOF - which relies on a weaker mechanical bond to adhere the overlay to the substrate.

Reduced In-Service Downtime - Improved adhesion of the coating ensures a strong and stable bond. This means the wind turbine main shaft spends less time in our shop and more time in the field.

Click here to see the process for yourself.

ABOUT US

For more than 40 years, Fusion Industrial Laser Services and our parent company Whitfield Welding Inc. has provided high-value repair, refurbishment, and part enhancement using cutting-edge laser and welding solutions for our customers in the automotive, mining/exploration, oil & gas, energy, aerospace, and defense industries.