MIG Welding

MIG welding can be a manual, automatic or semi-automatic additive process. A continuous spooled wire electrode, solid or cored with powdered alloys and flux is used. Digital power sources sophisticated feeders enhance quality to levels not possible in the past.

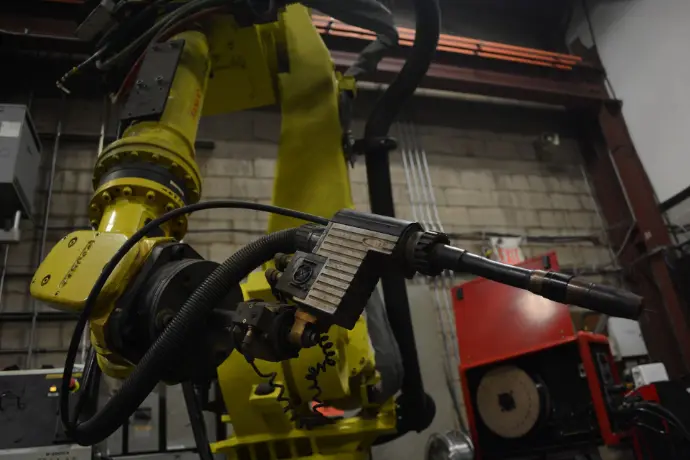

Whitfield Welding Inc. has coupled this process with robots and proprietary cam software to maximize deposition rates and efficiencies. This process is used regularly for bulk buildups and large surface area coverage for hobbing repair of very large tooling.

All of the procedures follow proper metallurgical heat treatment principles.