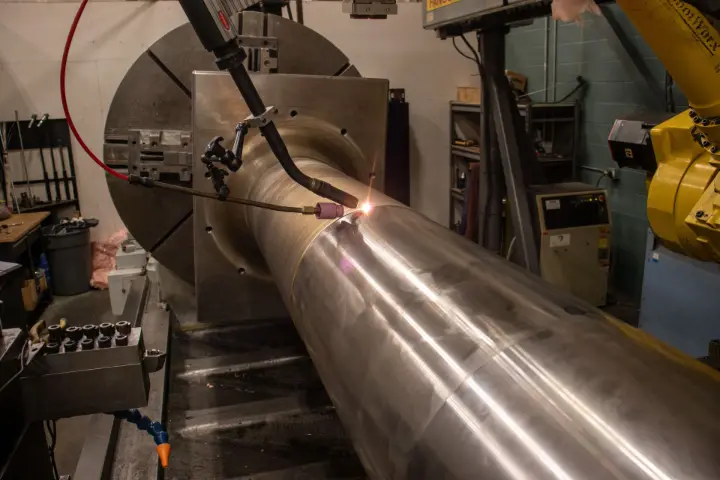

Fusion Industrial Laser Services’ umbrella corporation, The Whitfield Group, was initially founded back in 1985 by President Ron Whitfield as a welding company (Whitfield Welding Inc.) offering TIG, MIG, full process weld, colour matching and stress relief of plastic injection as well as stamping tools and dies.

In 2009, the Whitfield Group purchased their first high-powered laser and began the company’s expansion into laser services. Officially founded in 2017, Fusion Industrial Laser Services represents the laser division of The Whitfield Group with 6 high-powered lasers, offering services such as laser cladding, laser hardening, laser welding, laser engraving, laser cleaning, robotic CMT welding, 3D scanning, metallurgical lab services, additive manufacturing and a machining division providing full production and prototype machining capabilities.

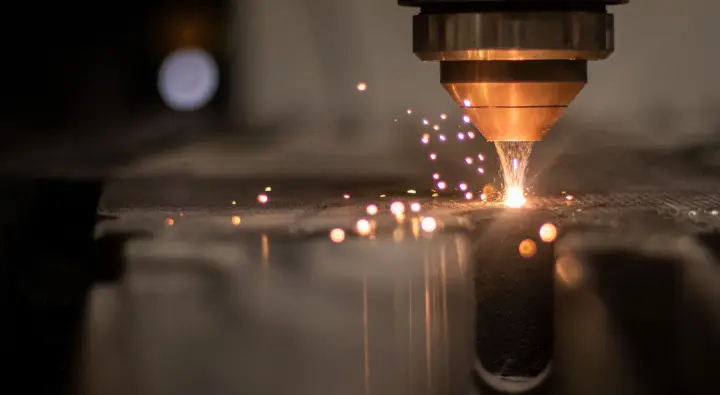

Since its inception, Fusion Industrial Laser Services has been honing and developing a superior laser cladding solution for preventing wear on the highest performance components. Our process uses a high-energy laser to melt and fuse a powder or wire feedstock material onto the surface of a component to form a metallurgical bond. This involves precisely controlled heat input into the hardest wearing part surfaces, eliminating the drawbacks of high temperature coatings such as chemical vapor deposition (CVD) and high-velocity oxygen fuel (HVOF). The result is superior wear and corrosion protection, no part distortion, along with reduced downtime and increased productivity for our customers’ high-value parts.

With 40 years of experience in the automotive, oil and gas, energy, and aerospace industries, the Whitfield Group continues to grow to this day! Our more than 50 employees in 3 state-of-the-art facilities help make us one of the most complete, complementary manufacturing partners in the world. As we continue evolving to meet our customer' needs, we look forward to what the next 40 years has in store!