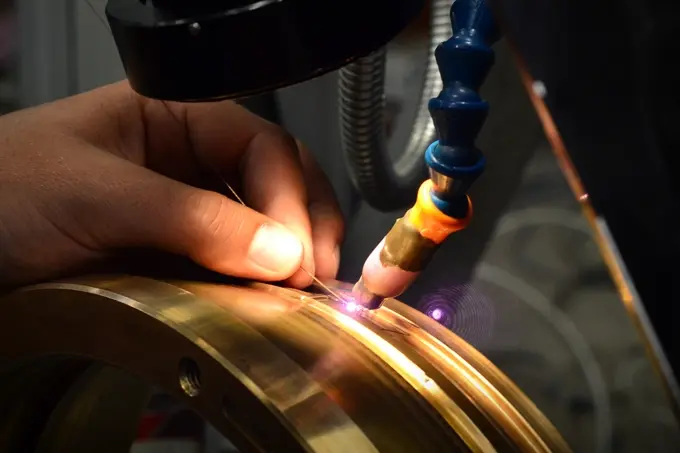

Laser Welding

Laser Welding is an additive process using a laser and fine filler wires, as small as .003. With the ability to weld both ferrous and non-ferrous material. This process is useful when repairing deep narrow ribs, texture repair, parting line seal off repair and anything else requiring minimal heat input and distortion control.

Our customers rely on us for our laser welding abilities. Our operators are top shelf when it comes to experience and artistic ability. Nothing is too large or too small for this precision additive work.

Applications

Highly recommended for plastic injection mold repair

Machine component and critical part repair and refurbishment

Aerospace critical component manufacturing and repair

Intricate medical device manufacturing and repair

Precious metal jewelry repair